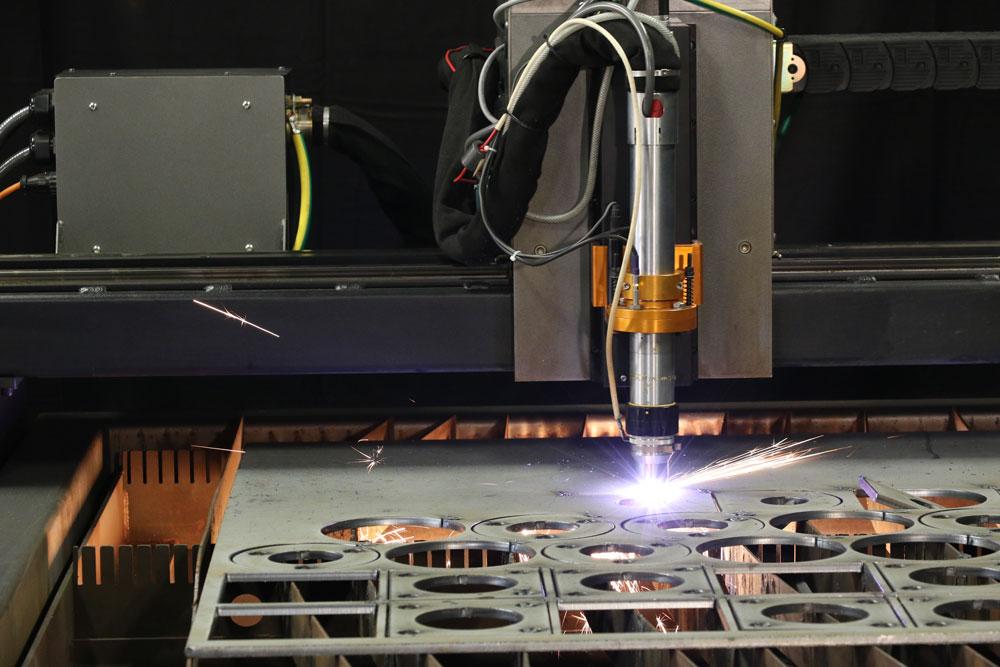

A Complete Guide to CNC Plasma Cutters: Precision and Power Combined

Imagine having a machine that is capable of slicing through metal as easily as a knife slices through butter. That is exactly what plasma cutters do. What should a person know about this machine and how it is used?

What is a CNC Plasma Cutter?

This machine heats gas to the point where it becomes electrically conductive, creating plasma. The CNC plasma cutter is controlled by computer software to ensure all movements of the high-velocity stream of plasma are precise. CNC is an abbreviation for computer numerical control, which is how the machine offers this level of precision. This device can be used to cut any electrically conductive material, such as aluminum and stainless steel.

CNC Plasma Cutter Components

A CNC plasma cutter comes equipped with a controller that dictates the movement and operation of the machine. A power supply creates the electric arc necessary for plasma creation, and this arc is generated at the plasma torch or cutting head. Materials are placed on a water table or a specially designed table to control the fumes generated during this process. The CNC plasma cutter also has a drive system responsible for moving the torch to the correct location based on information provided by the controller.

The Benefits of CNC Plasma Cutting

CNC plasma cutting offers numerous benefits. These machines provide precise and consistent cuts, which is essential when working with a detailed design or producing multiples of the same item. This process is incredibly fast, particularly when it is used to cut thin metals, and the machine can handle a wide range of conductive materials. It handles everything from complex curves to straight lines with ease. People are often surprised to find that these machines are very affordable and require little maintenance, making them ideal for smaller businesses, and they automate tasks to minimize manual labor.

Where Might CNC Plasma Cutters Be Used?

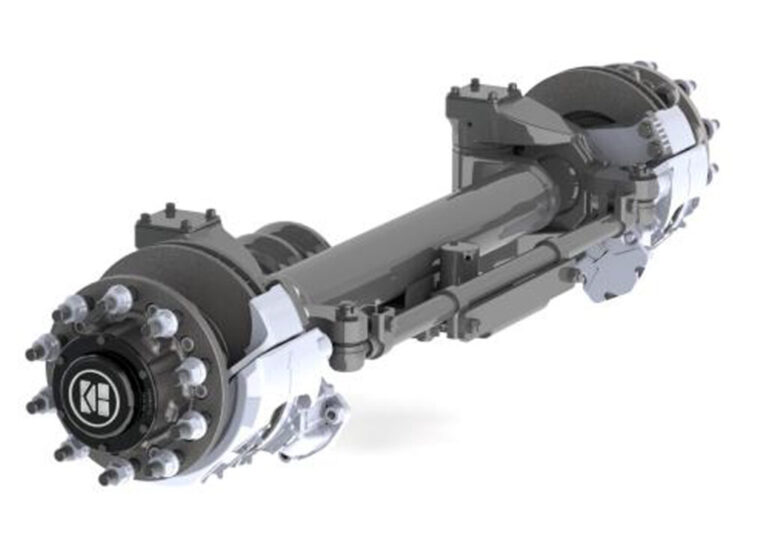

CNC plasma cutters are used in many industries. Metal fabricators use these machines to cut sheet metal, while the automotive industry benefits from CNC plasma cutters when fabricating custom parts. Construction crews cut steel beams and other structural components with CNC plasma cutters, and artists use them when making decorative items. A sign maker or an agricultural equipment repair provider may also use a CNC plasma cutter.

Why Choose a CNC Plasma Cutter When Other Options Are Available?

Many people wonder why they should invest in a CNC plasma cutter when other options are available. Laser and waterjet cutters can be used with a broader range of materials. However, these devices cannot cut at the same speed as plasma cutters do, and their operating costs are higher. Furthermore, they cost more at the time of purchase. Any company that primarily cuts metal finds that a CNC plasma cutter is a cost-effective solution.

Choosing a CNC Plasma Cutter

When choosing a CNC plasma cutter, a buyer must consider several factors. They need to determine the maximum thickness of the materials they plan to cut and choose a machine with a table size that can accommodate their largest workpiece. Learn which software programs are compatible with the machine, and select a user-friendly program. Research the build quality and durability of the machine by reading user reviews and investing in a machine with a robust warranty.

CNC plasma cutters are ideal for anyone interested in cutting metal. Hobbyists use these machines as do extensive manufacturing facilities. The speed, affordability, and precision of this tool make it a wise investment.

Stay in touch to get more updates & news on Ancientartz!